Gauge

-

Hot

gauge For Assembly Stamping Parts

gauge For Assembly Stamping Parts It is used to locate assembly parts. It is used to quickly and intuitively check holes, mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

Email Details -

Hot

Hardware Inspection Bracket

Hardware inspection bracket It is used to locate assembly parts. It is used to quickly and intuitively check holes, mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

Email Details -

Hot

Large hardware assembly inspection tool

Large hardware assembly inspection tool It is used to locate assembly parts. It is used to quickly and intuitively check holes, mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

Gages Engineer/buyer checking fixture/gauge Large hardware assembly inspection tool checking fixtureEmail Details -

Hot

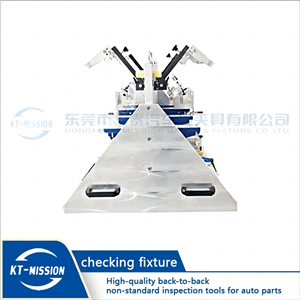

High Quality Back to Back Non-Standard Checking Fixture for automotive parts

1. Price: To survive and struggle in this hard time, we change quotation strategy and best price is available. 2. Timing: Each project will be followed up by two persons, who have technical background and bilingual, timing plan will be updated per week. 3. Quality: Quality control in each step, There are after-sales service partners in different areas, such as USA, Canada, Mexico, Spain, Czech Republic and etc, They can help you with engineer change to save time and cost.

Email Details -

Checking fixture

Mission has obtained ISO17025 laboratory accreditation, possessing high-precision testing equipment and a three-all quality management system with all system, all process and all employee participation. Standardization, digitization, making improvement bit by bit, Mission Gauge will keep improving and never stop.

Email Details -

Hot

Assembly hardware inspection tool

Assembly hardware inspection tool Assembly Parts gauges A fixture company that has reached European and American quality standards.Your Reliable Supplier for Checking Fixtures and Welding Jigs.Cubing(Car Cubing UCF PCF) Checking Fixtures for Automotives Welding Automation Fixtures for Automotives Non-standard Precision fixtures

Email Details -

Hot

Hardware Assembly Checking Fixture 1

Hardware Assembly Checking Fixture Hardware Checking Fixture A fixture company that has reached European and American quality standards.Your Reliable Supplier for Checking Fixtures and Welding Jigs.Cubing(Car Cubing UCF PCF) Checking Fixtures for Automotives Welding Automation Fixtures for Automotives Non-standard Precision fixtures

Email Details -

Hot

Simple and practical hardware products Checking fixture

Since 2008, Mission has been providing checking fixtures and welding jigs to OEMs and Tier 1 / Tier 2 manufacturers from all over the world. Mission partners cover all regions of China, and with after-sales service center in Europe, the United States, Canada, and Mexico. Europe, USA, Canada, and Mexico, providing value-added services such as design changes and after-sales services for global customers.

Email Details -

Hot

Hardware single product inspection tool

Hardware single product inspection tool checking fixture A fixture company that has reached European and American quality standards.Your Reliable Supplier for Checking Fixtures and Welding Jigs.Cubing(Car Cubing UCF PCF) Checking Fixtures for Automotives Welding Automation Fixtures for Automotives Non-standard Precision fixtures

Email Details