bumper

-

Hot

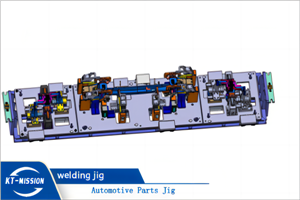

KT-Mission Robot welding jig

Advanced machining equipment, reasonable craftsmanship and strict quality control strictly control every production procedure. Do once and do it right, It is the biggest delivery guarantee for Mission Gauge There are 30 sets of 3 axis CNC machines and 4 sets of Gantry machining centres with max. machining scope 6 meters, and there are 6 sets 5-axis CNC from Germany DMU and Italy Breton , with auto-programming software, meeting the high-precision processing requirements of various large-sized special-curved workpieces. At the same time we Introduced SAP and Eman management systems to control the production progress in real time. High-efficiency, smart manufacturing, all in Mission. technology- leading and quality- brand ---- Fully in Mission.

Email Details -

Hot

Bumper Gauge

It is used for product positioning of bumper assembly. The main features of product hole, assembly surface, contour and so on are tested quickly and intuitively by hand-held testing tools to verify whether the product is qualified.

Email Details -

Hot

Rear bumper assembly inspection tool

Rear bumper assembly inspection tool It is used to locate assembly parts. It is used to quickly and intuitively check holes, mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

checking fixture engineer /buyer checking fixture Rear bumper assembly inspection tool Quality CoordinatorEmail Details -

Hot

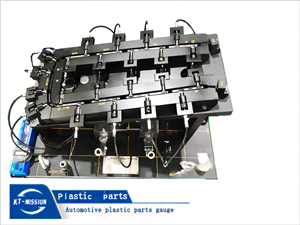

Professional Plastic Parts Checking Fixture Measuring Tool for BMW

Q: I have an idea for a new product, but I don't know if it will work. Can you help me? A: yes! We are always willing to work with potential customers to assess the technical feasibility of their ideas or designs and we can advise on materials, tools and possible costs. Q: what are the benefits of my locally made parts? A: Dongguan Mission Gauge & Fixture can provide quick response time to any changes in specifications, batch sizes, or materials. We can ship large or small quantities of goods anywhere in North America or Europe overnight to accommodate unforeseen changes in demand. Q: my components have been developed in the EAC. Can you use the drawing? A: yes! DWG, DXF, IGES, Solid Works and STP, x_T files can be used to generate budgets, models and tooling tools that can save time and money in production Its components. Q: which plastic is best for my design/component? A: the choice of material depends on the application of the design and its environment. We can discuss alternatives together and suggest the best materials.

Email Details -

KT-Mission Robot welding jig can be customized according to customer needs

KT-Mission Robot welding jig can be customized according to custom

Email Details -

Bumper Jig

This is a car bumper spot welding jig that will be used to fix welded parts to complete the welding process and become a weldable assembly part.

Email Details