Quarterly outstanding employee recognition conference

|Quarterly outstanding employee recognition conference

At 5pm on November 9, 2023, we held the quarterly Outstanding Employee Recognition Conference. Before the commendation conference, we held a tug-of-war competition between various departments of the company. Because the tug-of-war personnel had been selected before the conference, we drew lots directly, and then the tug-of-war was held. The top three in the tug-of-war competition have rich rewards, 1200, 1000, 800 yuan respectively. In the process of tug-of-war, the employees actively participate, the cheerleaders of each department are cheering for the team members, the team members are full of effort, and they have the spirit of not giving up.

Until 6:30 in the evening, the tug-of-war was over, and then we officially launched the commendation conference for outstanding employees. Under the orderly chairmanship of the host, we first invited the representatives of the heads of various departments to speak on stage, and the heads of various departments briefly explained a work situation in this quarter, as well as the excellent places and areas in need of continuous improvement in this quarter. After the head of the department finished speaking into the performance, is a handsome man brought the song, this song is called young you, the lyrics are very meaningful, he also said after singing, each of us has a young time, I hope everyone should dare to pursue dreams, to have unswerving spirit, no matter what environment, to make themselves valuable.

After the affectionate singing came the exciting commendation moment, the commendation content is divided into quarterly, monthly outstanding employees, and some excellent apprentices. They are positive in life, serious and responsible in their work, and there is always a person who will be busy in the company on the night when they all go back to rest. They take care of their customers, and in order not to interfere with their rest, they often need to be jet-lagged and have video conferences with customers in the early hours of the morning. They respond to customer messages at 2:00 or 3:00 in the morning, and their behavior is there for all to see, and they deserve the honor. After the recognition of the outstanding employee representative also said that the customer is always the first, must always keep in mind the concept of customer first, she also called on all employees to treat every customer to be careful, with their own behavior to move customers.

Time is fleeting, unconsciously came to the end of the commendation conference. Finally, the general manager of our company was invited to the stage to make the final summary. In the summary, it is also said that the development of a company requires the hard work of every employee, and every department also needs to cooperate with each other to have a common goal. At the same time, we must always adhere to the concept of customer first, and solve more problems for customers in an effective time. Although this quarter has been excellent, but there is still a lot of room for improvement, we need to continue to work hard in the next quarter.

When you see the company's short film news, you can also go to the company's products to take a look, if necessary, please leave a message, we will get in touch in time.

|Company Info

Mission Automation specilizes in designing & building automotive & non-automotive checking fixtures & welding automation systems,it's skilled at all kinds of precision machining works: inspection equipment, welding and assembly. With the plant area of 8600 ㎡ ,230+ employees in total, automation production equipment and aerospace & military precision machining standards, Mission Automation became a well-known supplier of checking fixture & welding jig in the world.

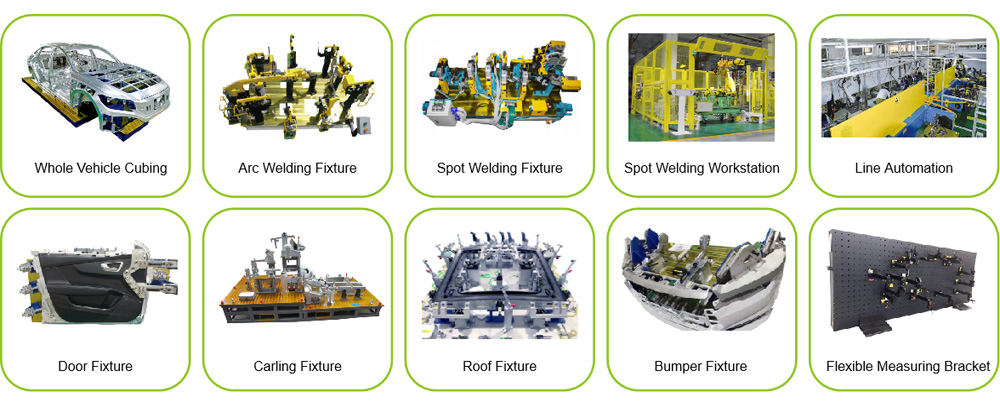

Mission Automation Business includes Whole Vehicle Cubing, Arc Welding Fixture, Spot Welding Fixture, Spot Welding Workstation, Door Fixture, Carling Fixture, Roof Fixture, Bumper Fixture.

|CAPACITY

Engineering Capacity

1.Checking Fixture

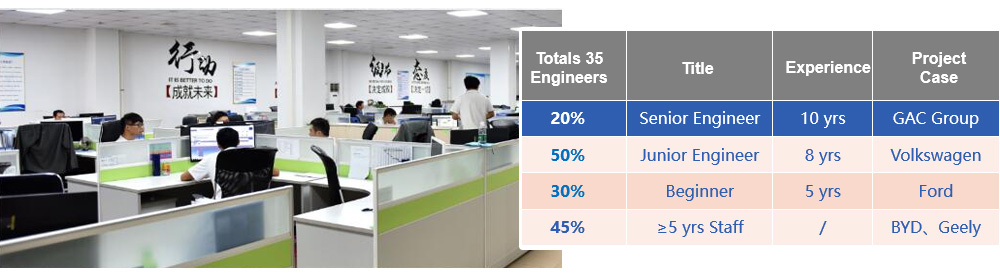

Engineering Team: For checking fixtures, it has 35 engineers in total, 20% are senior engineers, 50% are junior engineers and 30% are beginners, 45% of these checking fixture engineers have more than 5 years relevant experience;

Category: Main Model(Cubing, UCF, PCF) ; Plastic Part Gauge ; Metal Part Gauge ; Raster Holding Fixture.

Competitive Advantages:

Software Automation

UG secondary development automatic design increases the efficiency by more than 30% ;

Design Standardization

90% components are standardized during the designing stage in order to shorten lead-time and reduce cost;

Customer Requirement & Satisfaction

To better understand customer’s specification and requirement, tech review in person and local support on site are available for big projects.

2.Welding Automation

Engineering Team: For welding automation, it has 26 engineers in total, 20% are production engineers, 12% are electric engineers and 68% are design engineers, 51% of these welding automation engineers have more than 5 years relevant experience;

Category: welding work station, welding assembly line, welding jigs.

Competitive Advantages:

Electrical Adjustment

Electrical PLC ability, testing ability, programming ability;

Robot Simulation

Robot off-line programming ability, beat analysis ability, interference detection ability;

Customer Requirement & Satisfaction

To better understand customer's specification and requirement, tech review in person and local support on site are available for big projects.

Manufacturing Capacity

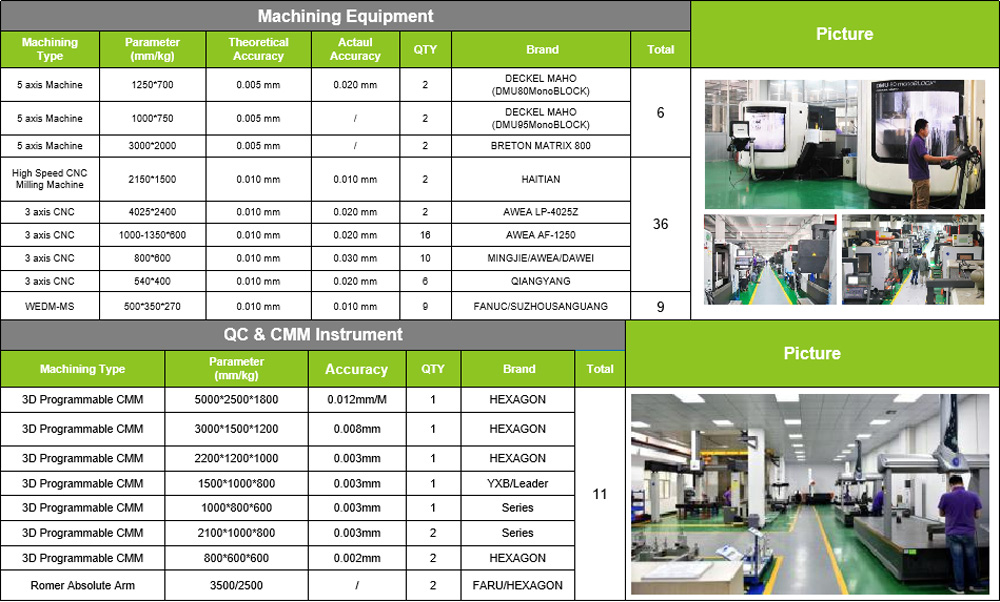

1.Equipment Capacities

2 shifts per day & 6 days per week;

Monthly maintenance & Service;

Shortest led-time is 25 days.

2.Machining Accuracy

0.008mm before anodize;

0.0005mm after anodize.

3.Operation Standardization

Standardization on processing, measuring, tooling, mapping, bracket programming, base programming and 5 axis programming.

|Certificate and Recognition

Mission Automation certified with ISO17025 and ISO9001and other state-level high-tech enterprise certificates. Besides, Mission has gained 30 national patents and many high-tech products awards from local government.

As for a leading enterprise of this industry,Mission Automation gained rich experience in automotive checking fixtures,welding jigs and automation systems for more than 15 years. We have not only capability, capacity,short delivery time and competitive price,but also one-stop shopping, pre-sales and after-sales value-added services.

Mission Automation takes 'Provide No Defect Products' and 'Delivery on time' as its sacred mission,and continues to explore the most efficient services and technologies to serve the customers globally in world-class standard. please feel free to contact us. Additionally, you can request a quote today for customized solutions.