Shanghai Auto parts Exhibition

|Shanghai Auto parts Exhibition

At the beginning of November 2023, our company received the invitation of Shanghai Auto Parts Exhibition, and at the same time, we are full of excitement to make the preliminary preparation required for the exhibition; On the 27th of this month, our company sent two elite representatives to attend the exhibition.

The exhibition is scheduled to be held on November 28th. We arrived at the exhibition venue in advance on November 27th. Under the arrangement of the exhibition staff, we stayed in a nearby hotel. In the evening, the representatives of our company again checked the information needed for the exhibition and the content required for communication. I got up very early in the morning on the 28th, after washing my face and brushing my teeth in the hotel, I ate breakfast in the hotel and prepared to go to the exhibition with other friends who participated in the conference. At nine o 'clock the doors of the exhibition opened slowly; Friends from all over the country successively entered, and the exhibition was officially launched in an orderly manner. Coming to the second floor of the exhibition and overlooking the exhibition, you can see that the exhibition venue is very lively, and there are many exhibitors, which can be said to cover almost all companies in the automotive industry.

To the first floor of the exhibition, almost all are temporary exhibition points of various enterprises; Representatives of various enterprises can also exchange and learn from each other, and there are many foreign friends to participate in the exhibition, take this opportunity to recommend their own company with foreign friends, but also to exchange and learn with foreign friends, it is really a very good exhibition. If there is a chance to participate in the exhibition in the future, our company will be ready to show to domestic and foreign enterprises with a new attitude, and exchange and learn with domestic and foreign enterprises with a new thinking; Finally, I also hope that friends at home and abroad will also come to know our company. Thank you for reading and browsing.

|Company Info

Mission Automation specilizes in designing & building automotive & non-automotive checking fixtures & welding automation systems,it's skilled at all kinds of precision machining works: inspection equipment, welding and assembly. With the plant area of 8600 ㎡ ,230+ employees in total, automation production equipment and aerospace & military precision machining standards, Mission Automation became a well-known supplier of checking fixture & welding jig in the world.

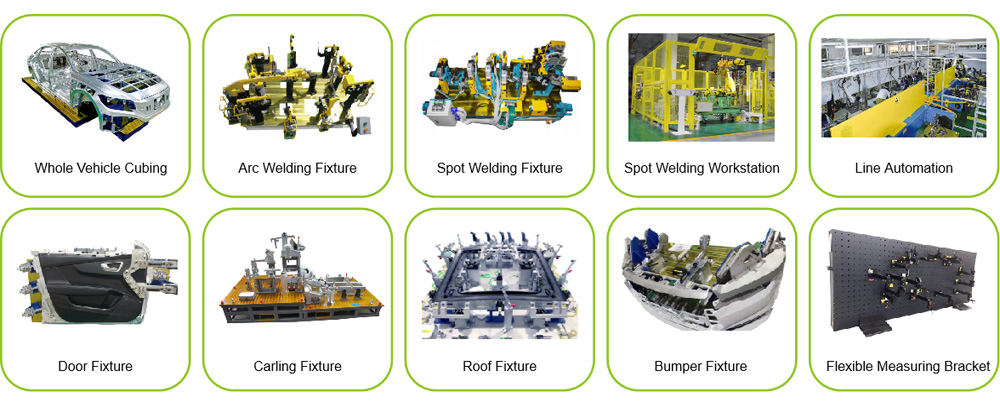

Mission Automation Business includes Whole Vehicle Cubing, Arc Welding Fixture, Spot Welding Fixture, Spot Welding Workstation, Door Fixture, Carling Fixture, Roof Fixture, Bumper Fixture.

|CAPACITY

Engineering Capacity

1.Checking Fixture

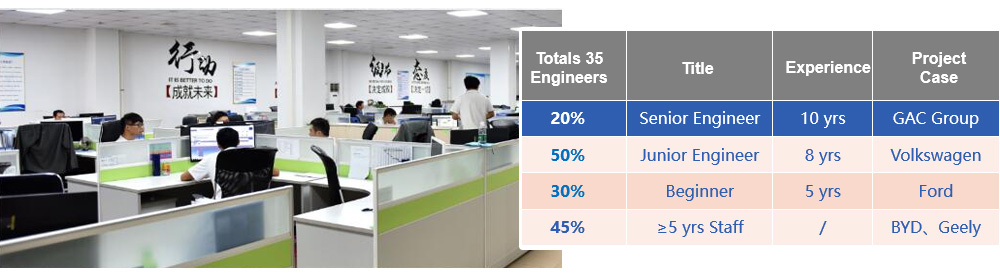

Engineering Team: For checking fixtures, it has 35 engineers in total, 20% are senior engineers, 50% are junior engineers and 30% are beginners, 45% of these checking fixture engineers have more than 5 years relevant experience;

Category: Main Model(Cubing, UCF, PCF) ; Plastic Part Gauge ; Metal Part Gauge ; Raster Holding Fixture.

Competitive Advantages:

Software Automation

UG secondary development automatic design increases the efficiency by more than 30% ;

Design Standardization

90% components are standardized during the designing stage in order to shorten lead-time and reduce cost;

Customer Requirement & Satisfaction

To better understand customer’s specification and requirement, tech review in person and local support on site are available for big projects.

2.Welding Automation

Engineering Team: For welding automation, it has 26 engineers in total, 20% are production engineers, 12% are electric engineers and 68% are design engineers, 51% of these welding automation engineers have more than 5 years relevant experience;

Category: welding work station, welding assembly line, welding jigs.

Competitive Advantages:

Electrical Adjustment

Electrical PLC ability, testing ability, programming ability;

Robot Simulation

Robot off-line programming ability, beat analysis ability, interference detection ability;

Customer Requirement & Satisfaction

To better understand customer's specification and requirement, tech review in person and local support on site are available for big projects.

Manufacturing Capacity

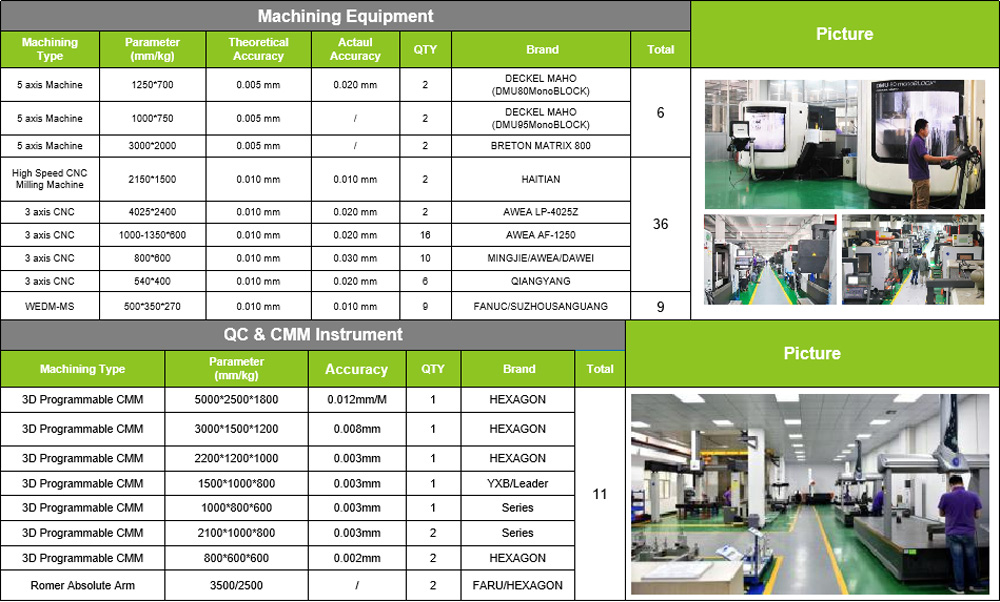

1.Equipment Capacities

2 shifts per day & 6 days per week;

Monthly maintenance & Service;

Shortest led-time is 25 days.

2.Machining Accuracy

0.008mm before anodize;

0.0005mm after anodize.

3.Operation Standardization

Standardization on processing, measuring, tooling, mapping, bracket programming, base programming and 5 axis programming.

|Certificate and Recognition

Mission Automation certified with ISO17025 and ISO9001and other state-level high-tech enterprise certificates. Besides, Mission has gained 30 national patents and many high-tech products awards from local government.

As for a leading enterprise of this industry,Mission Automation gained rich experience in automotive checking fixtures,welding jigs and automation systems for more than 15 years. We have not only capability, capacity,short delivery time and competitive price,but also one-stop shopping, pre-sales and after-sales value-added services.

Mission Automation takes 'Provide No Defect Products' and 'Delivery on time' as its sacred mission,and continues to explore the most efficient services and technologies to serve the customers globally in world-class standard. please feel free to contact us. Additionally, you can request a quote today for customized solutions.